Product Feature

- Versatile Material Handling

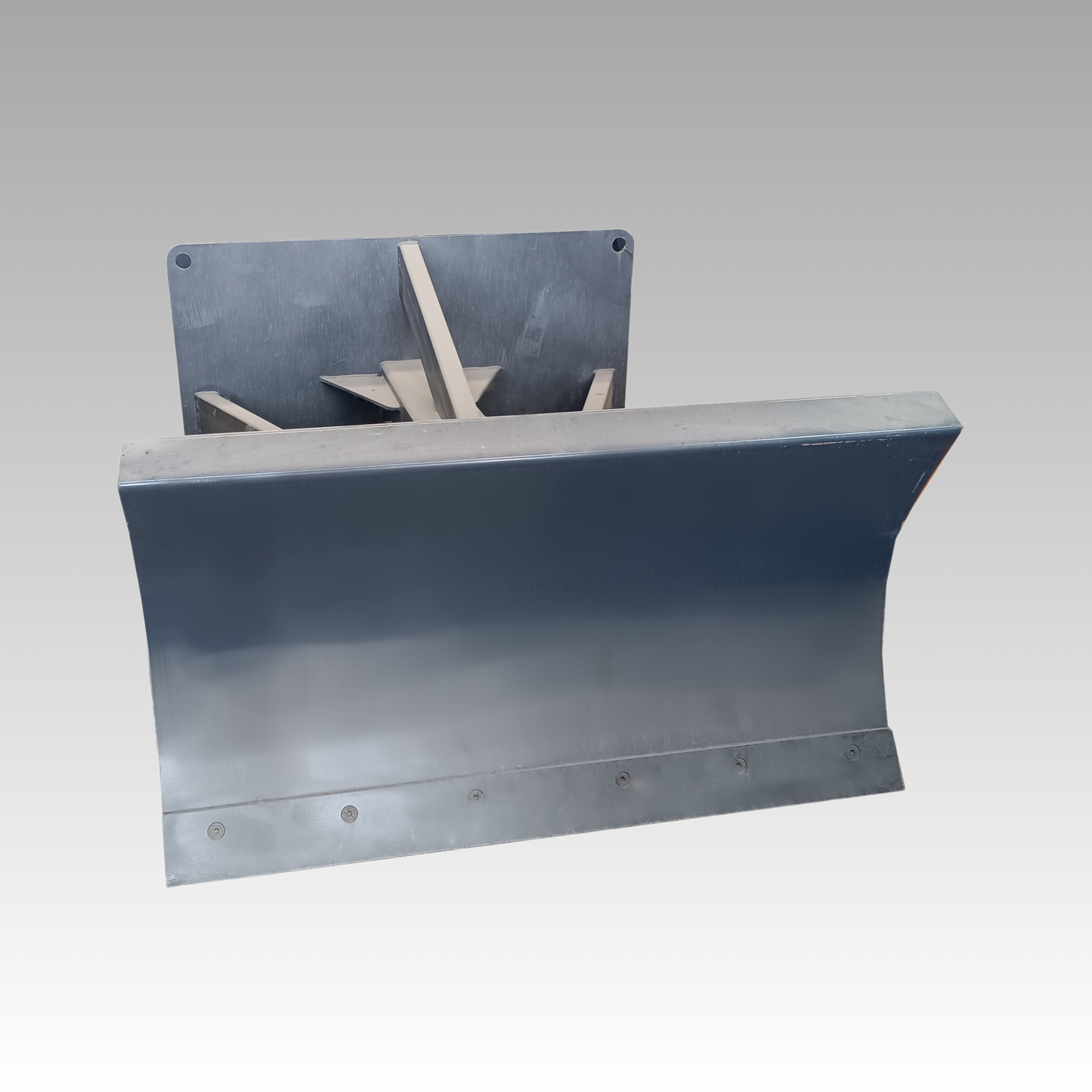

Specifically designed for unloading loose materials from train carriages and collecting materials in freight yards. - Replaceable Wear-Resistant Blades

Equipped with durable front and bottom blades that can be easily replaced, protecting the primary shovel structure from excessive wear. - Customizable Setup

Offers the option to install limiting blocks (collecting bucket, tipping bucket) according to the host machine's configuration, enhancing operational efficiency. - Engineered for Efficiency

Streamlines material handling processes, reducing downtime and improving productivity in challenging environments.

Specifications

| Model | BM40 |

|---|---|

| Overall Length (in) | 82.28 |

| Overall Height (in) | 38.03 |

| Overall Width (in) | 59.06 |

| Weight (including pendant) (lbs) | 1843 |

| Working Width (in) | 59.06 |

| Applicable loader (T) | Loaders 3 tonnes and above |

Performance Introduction

Turn your loader into a high-output wheel loader material pusher. This heavy-duty push blade is purpose-built for train carriage unloading, freight-yard cleanup, stockpile management, and bulk material transfer—moving more tonnage with fewer passes and minimal spillage.

Why crews choose it

-

Made for abuse: Reinforced frame protects the bucket interface and main shovel structure; wear-resistant front and bottom blades are replaceable for long service life.

-

Precision pushing: A stable, balanced moldboard and smooth leading edge deliver clean sweep performance for aggregate, grain, coal, ore, iron sand, soil, sand, debris, and even snow.

-

Rail & dock specialist: Engineered as a wheel loader train carriage unloading blade and railcar unloading blade—ideal in railway yards, docks, terminals, and tight transfer channels.

-

Operator friendly: Predictable tracking, low-effort control, and safe material pusher geometry reduce fatigue and boost shift-long productivity.

-

Low cost to own: Designed as a low-maintenance pusher with easy blade swaps and maintenance-friendly access points.

Built for your site

-

Freight & logistics: Wheel loader freight yard pusher, dock material pusher, transport channel pusher, truck loading pusher—keep cargo flowing.

-

Bulk stockpiles: Stockpile pusher, pile leveling pusher, heap management blade, and reclaim push blade for mills, terminals, and plants.

-

Processing & storage: Hopper cleanout pusher, silo cleanout blade, conveyor feed pusher to keep lines running.

-

Construction & municipal: Debris pushing blade, snow pushing device, yard cleaner blade, and site cleanup pusher for public works and contractors.

Materials it moves (and keeps moving)

Grain push blade, coal push blade, ore pushing device, iron sand pusher, aggregate push blade, soil pushing blade, sand pushing device, rubble, and mixed waste. The smooth, stable push blade profile helps maintain a tight windrow and precise placement.

Performance Video

Warranty

We’re here to support you every step of the way. In addition to a 1-year manufacturer’s warranty, our dedicated customer service team is ready to assist with any questions, troubleshooting, or guidance you may need throughout your ownership experience.More warranty Information

- Choosing a selection results in a full page refresh.

- Opens in a new window.