Product Feature

- High-Power, Energy-Efficient Motor

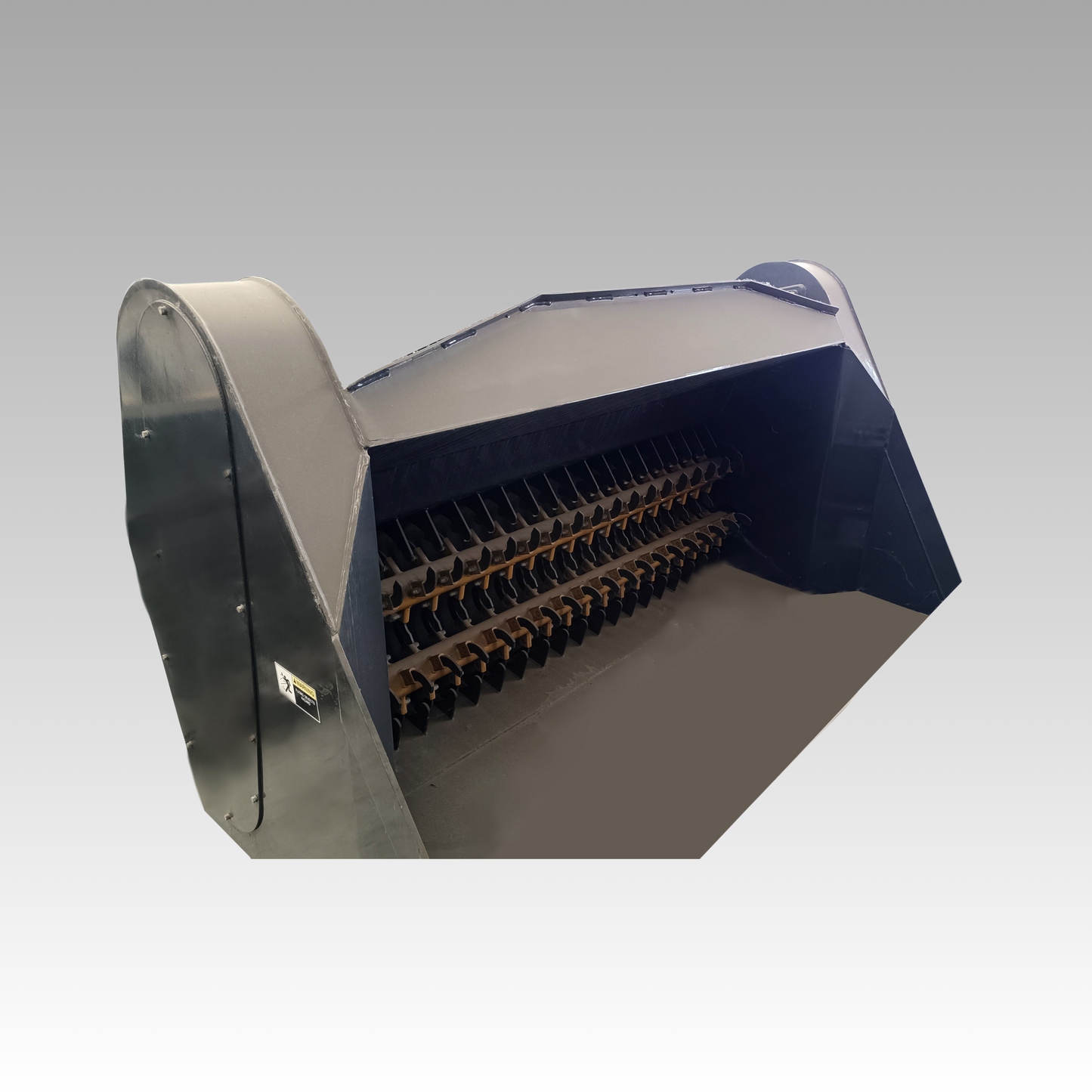

Provides strong performance with reduced energy consumption and environmental impact. - Double Twisted Gear Drive & Cross Rotation Structure

Ensures quick crushing and uniform mixing, leading to efficient screening of materials. - Detachable Blade Design

Allows for easy removal and replacement of worn blades, minimizing maintenance downtime and reducing costs. - Enhanced Operational Efficiency

Optimized for fast processing, this bucket significantly improves working productivity in crushing and screening applications.

Specifications

| Model | BM3920 | BM3920Ⅰ | BM3930Ⅰ |

|---|---|---|---|

| Overall Length (in) | 53.54 | 60.51 | 69.41 |

| Overall Width (in) | 70.47 | 71.93 | 104.33 |

| Overall Height (in) | 41.34 | 47.83 | 55.51 |

| Door Length (in) | 31.5 | 71.85 | 84.65 |

| Door Width (in) | 16.54 | 13.78 | 26.97 |

| Flush Hopper Capacity (cu ft) | 31.78 | 37.08 | 88.29 |

| Winch Length (in) | 30.71 | 55.12 | 84.84 |

| System Flow Rate (GPM) | 23.78-31.70 | 39.63 | 31.70-39.63 |

| Allowable Maximum Pressure (psi) | 2611 | 2611 | 2611 |

| Weight (including pendant) (lbs) | 1830 | 1808 | 3307 |

| Applicable models | 2t Loader | 2t Loader | 3t/5t Loader |

Performance Introduction

A next-generation wheel loader breaking and sieving bucket that combines a crushing and screening bucket with a high-energy mixer. Powered by a high-power, energy-efficient motor, it turns your loader into a mobile material processing bucket for fast on-site reduction, separation, and uniform mixing.

Why it wins

-

Rapid reduction, cleaner piles: The patented double twisted gear drive with cross relative rotation blades delivers high-throughput crushing and efficient sieving in a single pass—perfect for construction waste crushing, rubble, rock, ore, and asphalt recycling.

-

Energy smart: An energy-efficient screening bucket design lowers fuel burn and cuts your carbon footprint—true green crushing without sacrificing output.

-

Mix. Screen. Go: Integrated mixing action blends fines and additives for compost mixing, fertilizer mixing, feed mixing, and stabilized backfill.

-

Service in minutes: Detachable/replaceable blade packs and a quick-access layout make this a low-maintenance screening bucket with quick maintenance and minimal downtime.

What it replaces

Multiple standalone tools. One combo crushing bucket handles inline crushing, inline screening, and bucket mixing—reducing haul-offs, imports, and handling moves.

Built for the jobsite

-

Heavy-duty, long-life: A robust crushing bucket frame, wear-resistant internals, and protected drives stand up to mining, quarry, and demo cycles.

-

Productivity first: High rotor energy + controlled dwell time = a true high throughput bucket that keeps the loader productive.

-

Environmentally friendly: Lower passes, fewer truck trips, and low energy consumption support cleaner, leaner operations.

Where it shines

-

Utility cuts, roadwork, and paving: Pavement recycling, aggregate crushing, stockpile tuning, and trench backfill prep.

-

Demolition & recycling yards: Material sorting/separation, screening crusher bucket duty, and quick spec’ing for resale.

-

Mining & quarry: Rock/ore reduction and screening attachment work without moving material off bench.

-

Landscaping & ag: Soil/compost production and biomass screening with on-the-spot uniform mixing.

Uptime & service

-

Detachable blade design = fast swaps, lower part cost, and extended life.

-

Accessible drive & arbor keeps routine inspections short and safe.

-

Designed as a low maintenance screening bucket to maximize shifts and minimize shop time.

Compatible work styles

Use it as a wheel loader crushing bucket, screening bucket, sieving attachment, bucket screener, bucket processor, or bucket pulverizer—this single processing attachment adapts to your flow.

BeyondTech’s Wheel Loader Breaking & Sieving Bucket—your all-in-one solution for breaking, screening, and mixing with high power, low energy, and zero compromise on output.

Performance Video

Warranty

We’re here to support you every step of the way. In addition to a 1-year manufacturer’s warranty, our dedicated customer service team is ready to assist with any questions, troubleshooting, or guidance you may need throughout your ownership experience.More warranty Information

- Choosing a selection results in a full page refresh.

- Opens in a new window.